South Downs Woodturners - Turnings

Table of Contents

Robert Kemp and Barrie Fitch collaboration

Robert turned these pens, and Barrie used his laser engraver to add the names.

Black marker was used to cover the area to be engraved. This was then removed with acetone, and the engraving was then filled with gold Rub 'n' Buff and polished with Micromesh 8000 and 1200 grit.

Lovely work!

It’s been a year since I moved to Cornwall and I will be coming back on occasion to Sompting and will try and time it with the first Thursday of the month!

Still turning and learning….. cannot thank you and the club enough for all the help and guidance given.

I have joined a local Cornwall club as well and on Tuesday…. Broke my virginity!

Using the presentation techniques I observed from you and the club members…. Gave my first ever demo to fellow woodturners – on colouring…

Was extremely nervous – but explained the shaking hands were not nerves, but a colouring technique!

It seemed to be well received and I have positive comments…. Didn’t notice anyone yawning…. A good thing!

Hopefully further demonstrations will settle my nerves.

Please send everyone my best.

Jim Young's route to a Monkey Puzzle Bowl

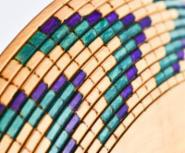

Peter Brown's series of Basket Weave Platters

Alan Wesley on decorating his turning

At our May meeting Alan showed us an incredible range of decorating ideas he has tried recently some of which are pictured below:

As you can see the techniques he used are varied and imaginative, but how did he do them, and what materials did he use. To help answer those questions and more Alan

and I have put together a selection of his work in a PDF document below so you can see in a little more detail

Up until 18 months ago I have never considered a smaller second lathe, for the last 15 years I have only used large heavy lathes.

I started with a Union Graduate, then a Turnstyler, now a VB 36. When the club was formed I became the custodian of the club’s lathe which is the Axminster 1416 vs. As I could be called to

demonstrate at times I thought it best to familiarise myself with the lathe to fined what its limitation were, compared to what I am used to using. Apart from the size and weight of the Blanks the

lathe performs well. I found it very useful when turning small items that required reverse chucking, with this in minded I decided to buy a second lathe.

After a little research I decided to go for the Jet 1221 vs. I found that both Lathes are manufactured by the same company, the main difference is the motor and the casting. The Axminster motor is

though an inverter and the Jet has a normal electric motor, both have forward and reverse. I’m sure the electrical engineers will tell me I get more torque from an inverter type motor. I have used

both machines on similar projects and have found little difference in performance.

The main reason why I chose the Jet is that it appears to lose very little in the motor and gains with a much heavier casting. The bed is larger and changing the belts is very easy compared to the

Axminster. Both lathes would benefit from being bolted to a bench but less so with the Jet. The weight difference is large, the 1416 is 41kg the 1221 is 55kg.

For interest I use the Axminster precision chucks on both my lathes (regretfully these are on longer available from Axminster).

Jim Young

Tool & Wood Recycling - Wanted and For Sale

Our members are always on the look-out for sources of wood that would otherwise go to waste. If you have some wood, furniture with large solid wood elements like the legs, or a tree or large shrub you would like to dispose of, we will try to put you in touch with one of our members who would make good use of the wood and turn it into something beautiful.

Woodturning or wood carving tools and lathes etc. are always sought after. If you have any that you no longer need we would be happy to put you in touch with our members who would make good use of them. Please contact us at: Secretary@SouthDownsWoodturners.com

For Sale

If you would like to sell your surplus wood or tools here please email us at: Secretary@SouthDownsWoodturners.com

You will need to provide photos (smaller items in groups please) with clear details of each item and how much you want for them, together with your contact details. The Club requests a donation of

10% of the proceeds for this service which is open to members and non-members alike

Details of items for sale are the sole responsibility of the seller, and South Downs Woodturners offersno warranty, express or implied